The Taccle AI project sought examples of whether and how AI is used in vocational schools. In Germany, there is a tendency to orientate oneself towards Industry 4.0. AI is usually not taught directly, but dealing with the latest Industry 4.0 is encouraged. This creates a basis on which to build to address AI technologies in the future. So-called Smart Factory systems have been set up at numerous vocational schools in Lower Saxony and Bremen. Interviews have already been conducted with some vocational school teachers to learn more about the implementation.

At the Vocational School (BBS) 2 in Wolfsburg, so-called smart factory systems were virtually integrated into the classroom in the summer of 2019. These new classrooms are now called laboratories at the school. The smart factory systems were built by trainees for automation technology, mechatronics, and IT. The industrial facilities at the neighboring Volkswagen plant serve as a model. The students can use the Smart Factory models to gain practical experience in dealing with the latest Industry 4.0 technologies.

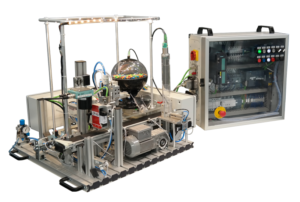

Smart Factory Plant

The Smart Factory plant in Wolfsburg is a model of a smart filling plant. Production is started via a self-programmed smartphone app. First, a can is placed on a conveyor belt. This is then filled with chocolate coins and fitted with a lid. A QR code is then printed on the can. This code can then be scanned in again at the end to display the production data (filling date; the number of chocolate counters, etc.) on a tablet. For example, the energy data acquisition can be viewed for each can. Besides, a digital twin is created for each can. The machine can generate a self-diagnosis and provide automatic and dedicated support requests. To enable the trainees to record what they have learned or to acquire further knowledge on the topics, there is a direct link to the school’s online learning platform via a QR code. The online learning platform serves as a basis for digital learning and teaching at school. The learning platform is also open to other vocational schools.

is then filled with chocolate coins and fitted with a lid. A QR code is then printed on the can. This code can then be scanned in again at the end to display the production data (filling date; the number of chocolate counters, etc.) on a tablet. For example, the energy data acquisition can be viewed for each can. Besides, a digital twin is created for each can. The machine can generate a self-diagnosis and provide automatic and dedicated support requests. To enable the trainees to record what they have learned or to acquire further knowledge on the topics, there is a direct link to the school’s online learning platform via a QR code. The online learning platform serves as a basis for digital learning and teaching at school. The learning platform is also open to other vocational schools.

Reflexion

The supervising teacher, reports in an interview that one factor for success is the cooperation between Volkswagen, the vocational school, and other industrial partners. In this way, technical knowledge and knowledge of the industrial plants could be combined with the didactic know-how of the school. Besides, the agile project management and the outstanding commitment of the trainees played a significant role in the success.

Weblinks to the project:

A video about the project (german): https://www.foraus.de/de/foraus_108586.php